M.O.RE INTEGRATED INTO THE DRUM: WITH THE BRAIN OF THE DEPARTMENT INTEGRATED INTO THE LCAS INTERFACE, CONTROL OF THE TANNERY PRODUCTION IS REALLY AT YOUR FINGERTIPS

- Erretre

- Jul 28, 2025

- 3 min read

In over fifty years of innovation for the leather making industry, Erretre has always accompanied the market towards a more efficient, sustainable and intelligent future. Today, that evolution takes another step forward: the M.O.Re (Milling Organisational Resources) software, the digital heart of Erretre for the milling drum department, has been integrated directly into the LCAS operator interface.

A concrete breakthrough, designed to simplify the tanner’s work, enhance man-machine synergy and increase the level of automation and control even in the most demanding production contexts.

Technology that adapts to the habits of those who work

Until yesterday, the M.O.Re software – a powerful platform for scheduling, controlling and analysing milling drums – was only accessible from a centralised location via a PC. An effective option, but not always fully exploited due to its “distance” from the Milling department, the centre of the action.

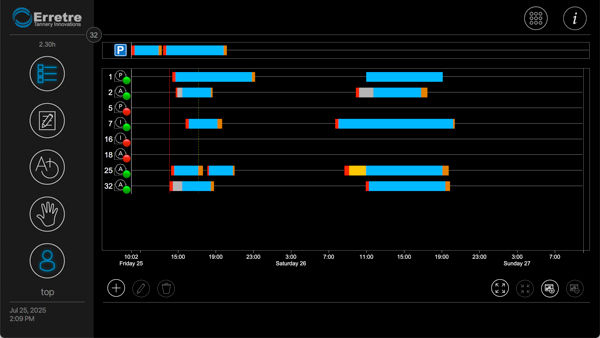

Today, M.O.Re lives directly within the LCAS control panel fitted in all Erretre drums. This means that all the key features of the software – from cycle planning to recipe management, real-time monitoring to traceability – are available directly on the machine interface, via the 21" touchscreen.

“We wanted M.O.Re to become part of the tanner's everyday working tool,” explains Giulio Galiotto. “Whereas before it was perceived as something external, and add on, now it is there where it is needed, when it is needed. Accessible, intuitive, ready to be used directly by those who are most in contact with the drums without having to access a computer and waste precious time.”

An interface to see, decide and act

Erretre's LCAS system is not just an advanced graphical interface, but a true interactive platform for local process management. Today, with the integration of M.O.Re, LCAS also becomes a planning console.

Thanks to the local area network (LAN) connection, the drums can communicate with each other: the operator can consult the calendar of cycles in progress, organise work by batch, check for conflicts or overlaps, change recipes on the fly and reschedule processes in a simple and visual way like before, but all without having to leave the machine.

“This feature responds to a real need,” continues Galiotto. “The ability to manage everything directly from the machine, without having to transcribe data or move around, reducing the margin for error and speeding up operations.”

Total control, even if not in front of a PC

One of the most obvious advantages of this integration is that it allows operators to control the entire production cycle even without a dedicated computer workstation. Everything they need is already on the machine panel, with no need for hardware modifications or updates. The integration was made possible by the computing power already provided by the LCAS hardware and does not require structural changes.

This approach is a key lever for promoting the digital scheduling and tracking intuitively, bringing technology closer to everyday practice.

A concrete response to the needs of modern tanneries

The new solution developed by Erretre responds to various needs expressed by the leather making market:

Greater control and organisation of Milling cycles, without overburdening operators.

The software does not replace experience, it amplifies it: the intuitive interface allows experienced operators to put their know-how to work more effectively and with greater operational continuity.

Fewer errors in batch traceability, with automatic archiving of process parameters.

Direct access to production data, even without accessing to an external computer system.

Flexibility in planning, to adapt to dynamic workloads and customised cycles.

Furthermore, for those who continue to use M.O.Re from their desktop, nothing changes: the PC version remains available and synchronised with the machines.

Closer to an interconnected production ecosystem

The integration between LCAS and M.O.Re sets a new standard for local control, but is also part of a broader vision of global supervision. Erretre, which has been committed to the development of 4.0 technologies for now 30 years, looks to a future where machines communicate with each other, where traceability is native, and where automation is not just a promise, but a concrete tool available to the tanner.

“The goal is not just to make smarter machines,” concludes Galiotto, “but to make them easier to use, closer to the operator, and more useful every day. This integration is proof of that.”

Comments