Leather finishing lines for tannery

Spray booths | Tunnel dryers

Erretre finishing spray lines are the result of the experience gained in over 70 years in the field of leather finishing processes and in the resolution of related problems.

A range of reliable and customizable machines that are efficient and simple to use, able to solve problems such as fume abatement, cleaning and energy saving in the tannery, improving leather finishing techniques and the quality of hides and skins.

The production of Erretre tannery machinery focuses on the modern needs of the leather processing field, searching for innovative and transversal solutions in line with the global needs of increasing the environmental sustainability and reducing consumptions.

Spray booths and carousels

Choose the most suitable type

Elliptical

Rotary

Alternate

New in

The carousel is the core of the leather spraying booth. It is the rotating device used for industrial painting on which spraying guns are installed, and it is used to uniformly spray each area of the hides and skins. Thanks to Erretre’s R&D unit, today we can provide the new elliptical-shaped leather spray booth, which guarantees a significant space saving and a reduction in color consumptions maintaining the same results as the rotary cabin.

New in

Élite spray carousel

Change your point of view

The traditional spray finishing cabin evolves: the new elliptical shape designed by Erretre allows to reduce the number of spray guns and the quantity of chemical products used, while maintaining the highest leather finishing quality in a compact space.

Same spraying arc as the rotary carousel

With its revolutionary elliptical shape, Élite leather finishing cabin achieves the same spraying arc as the standard rotary version. In this way, the same leather finishing quality is maintained, guaranteeing a highly uniform coverage.

Less arms, less consumptions, more results

With the same spraying arc and speed, Élite spray booth has reduced dimensions compared to a traditional finishing cabin. This allows to reduce the number of spray guns, consequently lowering the quantity of chemical products needed.

Ecotan | Ecospray

Élite carousel

New in

A big challenge from a mechanical perspective: Élite finishing cabin’s technology maintains the same spraying arc as the rotary booth and reduces consumptions. This finishing booth is designed for tanneries that do not have large spaces, but do not want to give up the quality of their products.

Same spraying arc as the rotary cabin

Automatic color change

Latest generation spraying control

Automatic washing system

Less consumptions and dimensions

Multi-way distributor in high and low pressure

Ecotan | Ecospray

Rotary carousel

The rotary cabin for leather finishing has always been the fundamental component of the tannery. Solid and robust, the rotary booth is a product built to last over time. Our painting carousels for leathers have a diameter from 1800 to 3400 mm and guarantee enormous flexibility in the tannery, without quality compromises.

Automatic color change

Automatic washing system

Multi-way distributor in high and low pressure

Ecotan | Ecospray

Alternate cabin

Alternative spray finishing booth in stainless steel, suitable for the tannery with limited available space. The cabin has a translating trolley with variable and adjustable speed according to production needs, designed to ensure a long lifetime and reliability.

Custom arms and guns

Erretre spraying booths and carousels can be customized up to 24 arms. We are able to satisfy the different production needs in every tannery, from the reduction of space to the maximum performance of the finishing lines.

8 | 12 | 14 | 16 | 24

Tailor-made conveyor width

It’s possible to choose the carousel’s diameter that best suits the possibilities. The in-line conveyor is available from 1800 to 3400 mm, with a ratio between conveyor and carousel of 1:1.41 and 1:1.5. We always suggest an increased diameter ratio according to needs.

1800 to 3400 mm

.png)

Spray finishing booths

Flexible, modular and custom-built

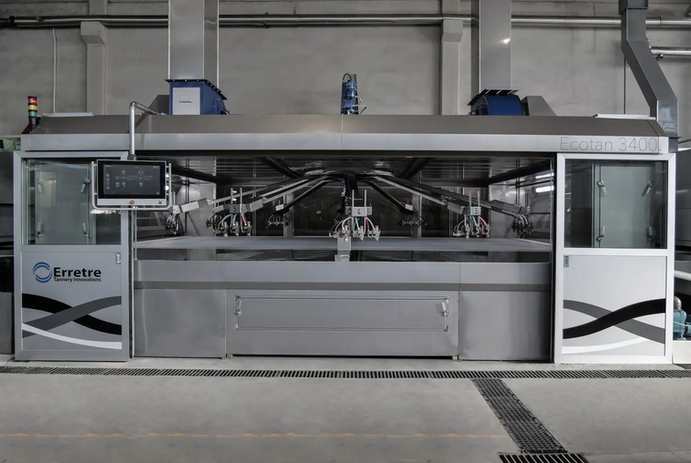

Ecotan and Ecospray leather spraying cabins are fully automated and equipped with LCIS software with a 21.5” touch screen. The system allows the centralized programming of work cycles, the management of recipes and processes, the study of production data and analytics and the setting of different working parameters on the entire finishing line, from spray cabins to tunnel dryers.

LCIS software can be connected via Ethernet to a LAN network, in order to transfer data to other programs and allow Erretre’s remote assistance. Local automation is managed by a single interface to ease up the work of technicians and operators, and can be completed with additional control devices such as bar code readers, scales for consumption control, painting economizers, inline crosslinkers.

Structure in stainelss steel

Software intended for Industry 4.0

Energy saving integrated system

Wide opening doors at 70%

Highly

customizable

Finishing automatic spray cabinet

Ecospray

Ecospray spray booth provides a water veil system and is designed for the installation of a separate spraying fume abatement device. This finishing cabin can be installed in different configurations, thus facilitating the access for cleaning and maintenance.

Available in various sizes, Ecospray finishing cabin is designed for a perfect and uniform coverage of all types of hides and skins and for the application of any finishing product such as coatings, fixatives, dyes, oils, waxes.

Independent scrubber

Fume abatement in 2 steps

Finishing automatic spray cabinet

Ecotan

Ecotan tannery booth stands out for its efficiency in spray fumes abatement without the need for an external scrubber. With double filtration systems based on water and dry filters, Ecotan offers the possibility of partially recycling the treated air in the cabin itself.

The design of the spraying fume abatement system as an integral part of the booth allows to keep the overall dimensions reduced, with a high work liberty and visibility from both sides, making the booth ideal for limited spaces or for lining machines side-by-side.

Integrated scrubber

Fume abatement in 2 steps

Reduced emissions and consumptions

Easy maintenance

Drying tunnel

NER

NER tunnel dryer has been designed to work at a high speed and to guarantee a leather drying process free from thermal shocks. This is fundamental to avoid losing an excessive surface area or to cause sudden changes in leather temperature or moisture.

NER is a modular tunnel dryer where each module is provided with an individual regulation system of temperature, air and ventilation. The machine has been designed to ensure a controlled drying of the hides and at the same time achieving considerable energy savings.

Spray booth

Manual

Our manual spraying cabins are suitable for sampling or R&D laboratories: two models in stainless steel are available depending on the filtering system. Both versions offer an ergonomic illuminated worktop and a shelf for chemicals storage.

The dry filter cabin has a structure with a support net for the hides and it is easy to clean; the water veil cabin is activated according to use, in order to limit noises and energy consumptions, and provides a droplet separator and an automatic leveling system.

Equipment for leather finishing lines

Washing systems and wire scrapers

In addition to a classic dry wire scraping system with rotating blades, a high performance water-based wire washing system can be configured in all Erretre finishing booths.

Double motor with adjustable speed

Synchronized speed of the conveyor

Precise distance between blades

Automatic cleaning cycle

Contact us

Do you want to know more about Erretre leather finishing machines for tannery? We are available for any information. Ask us what you need!